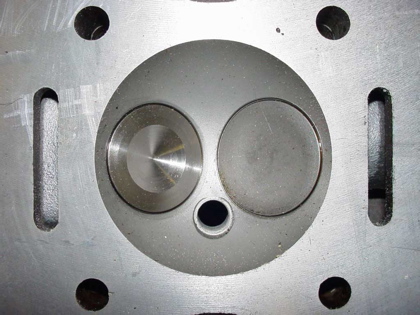

My head. Note the valves... they are recessed pretty far into their seats. (Photo: Geoff Pickard)

The engine "all boxed up" as Geoff says. (photo: Geoff Pickard.)

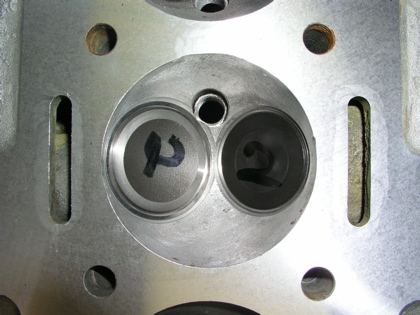

Ray Livingston sent me this photo to show me what my head/valves *should* look like.

After some time in the machine shop, here is my head/valves. New Valve seats have them flush with the combustion chambers again.

Here is a shot that shows the new seats well.

another.

Here is a shot of the odd split in the tub, in the driver's side footwell. I noticed it before, but did not realize that it extended all the way through. Geoff illustrated this by sliding a screwdriver through the hole.

The block, awaiting the head. Note the stock oil feed pipe on the towel. We are considering replacing the braided one with this stock solid one.

Uncovered. Note the dust caps on my brake fluid bottles. Geoff installed those for me.

another view

Nicholas was getting a lesson in how an internal combustion engine works. Up until today, he had only seen the internals of a Briggs & Stratton lawn mower (flathead) engine. This was his introduction to four-stroke Hemi-head, tri-power. I think he likes it.

another valve shot.

and another...

All the bodged bits in a box. The cams had JB Weld in the ends, instead of a brass plug(!) Not that I am disparaging JB Weld, but it isn't what you would expect from a high-dollar resto! One cam bearing is badly worn too.

Nicholas was enthralled by Geoff's son's Lotus Europa. Geoff suggested he climb in! He can't quite reach the pedals, but he looked ...

...at least "correctly scaled" compared to a big guy like me. =) Think Nick is ready for his license?

See what I mean about scale?